How to Select and Get Out Merchantable Walnut Stumps

If any industry is to prosper or even exist today, it must rid itself of every waste that makes an economic loss. This law of business applies equally to producer, manufacturer, and consumer. One of the causes of serious loss to the Walnut industry is the digging, transportation and disposal of worth less stumps and root wads. Figure 1. This is the way walnut logs with stumps should look when they are ready to haul and ship. Competition for markets among cabinet woods is so keen that anything that increases the cost of merchantable Walnut material endangers the life of the industry. It is the purpose of this circular to put before timber buyers and loggers the facts that will make it possible for them to avoid unprofitable production. This kind of material is unprofitable to them because the cost of digging and shipping junk must come out of the usable material that reaches the mill. Leave the junk in the woods. You will save the cost and get more for the rest of it.

Figure 1. This is the way walnut logs with stumps should look when they are ready to haul and ship. Competition for markets among cabinet woods is so keen that anything that increases the cost of merchantable Walnut material endangers the life of the industry. It is the purpose of this circular to put before timber buyers and loggers the facts that will make it possible for them to avoid unprofitable production. This kind of material is unprofitable to them because the cost of digging and shipping junk must come out of the usable material that reaches the mill. Leave the junk in the woods. You will save the cost and get more for the rest of it.

It Saves Money to do it Right Figure 2. The Bell-Shaped Stump Notice the regular bell edge at base. No root spurs or frost cracks. Bark has been peeled to show “nubbles” or ripples that denote figure to height of 22 inches. This is the kind of stump that is worth digging.

Figure 2. The Bell-Shaped Stump Notice the regular bell edge at base. No root spurs or frost cracks. Bark has been peeled to show “nubbles” or ripples that denote figure to height of 22 inches. This is the kind of stump that is worth digging.

It pays both the producer and the mill man to leave the worthless stumps and root wads in the woods. The producer gets just as much for his merchant able material and saves all the costs and labor that he is now spending uselessly. His net profit is greater. The mill man saves the cost of freight and of disposal of waste. His net cost is lower. Figure No. 1 shows the kind of trees that are worth grubbing and how the stumps should look.

What Is a Good Stump?

Size—20 inches and up inside the bark, 3 feet above ground.

Shape—Should be symmetrically bell-shaped.

Figure—Lower 18 inches shoudl be rippled (nubbles). See Figure 2. Clear around the stump. Stumps without figure even if large make veneer of low value.

Defects—Hollow or dote is a serious defect as such defects occur at the base and it is this part of the veneer that must be matched. Deep frost cracks, ring hearts, rotten spurs are serious defects.Stumps with evidence of iron are risky. Stumps made irregular by high root spurs should stay in the ground. Trees that are plain almost to the ground line should not be grubbed.

Figure 3. A mixed lot of logs showing five with stumps attached but minus the root wad. No. 1 is a good stump, No. 2 is too small and has bad spur crack. No. 3 too irregular. No. 4 not quite so bad. No. 5 shape all right but too small.Root Wads

Figure 3. A mixed lot of logs showing five with stumps attached but minus the root wad. No. 1 is a good stump, No. 2 is too small and has bad spur crack. No. 3 too irregular. No. 4 not quite so bad. No. 5 shape all right but too small.Root Wads

If a stump is of merchantable size and quality, its value is not in the root horns, dirt and stones that may be attached. This mess, usually known as a “root wad,” is of no earthly value. Leave as much in the ground as you can and cut off the rest after the tree is felled.

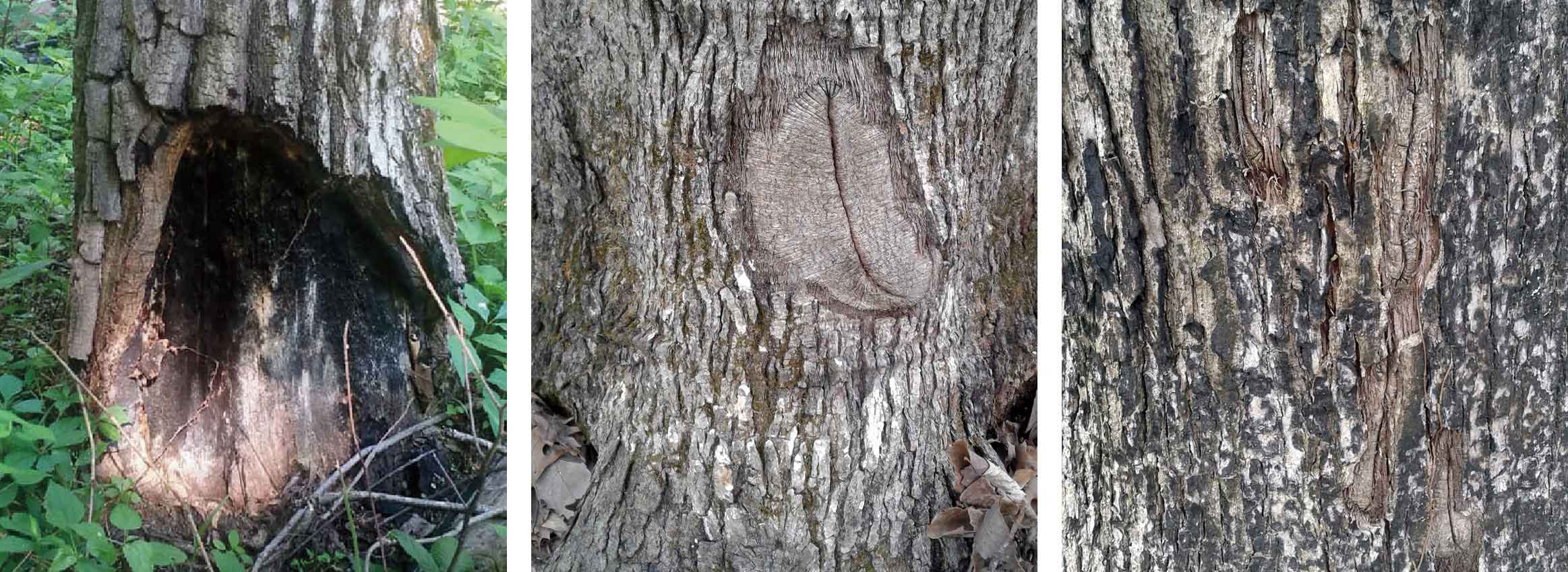

Cutting Off Root Wads Figure 4. A Very Poor Stump—Too many spur roots, a dead spur and evidence of hollow. Little or no figure and not belt-shaped. Cut this kind close to the ground and leave the stump.

Figure 4. A Very Poor Stump—Too many spur roots, a dead spur and evidence of hollow. Little or no figure and not belt-shaped. Cut this kind close to the ground and leave the stump.

If the stump comes out of the ground looking like Figure No. 6, cutting off the wad is not a serious problem. If it comes out with plenty of horns, cutting it off will be more of a job. To do it most economically the crosscut saw must be swedged wide. When cutting off root wads the cut should be made through the center of the lowest side root so that the butt end is square cut.

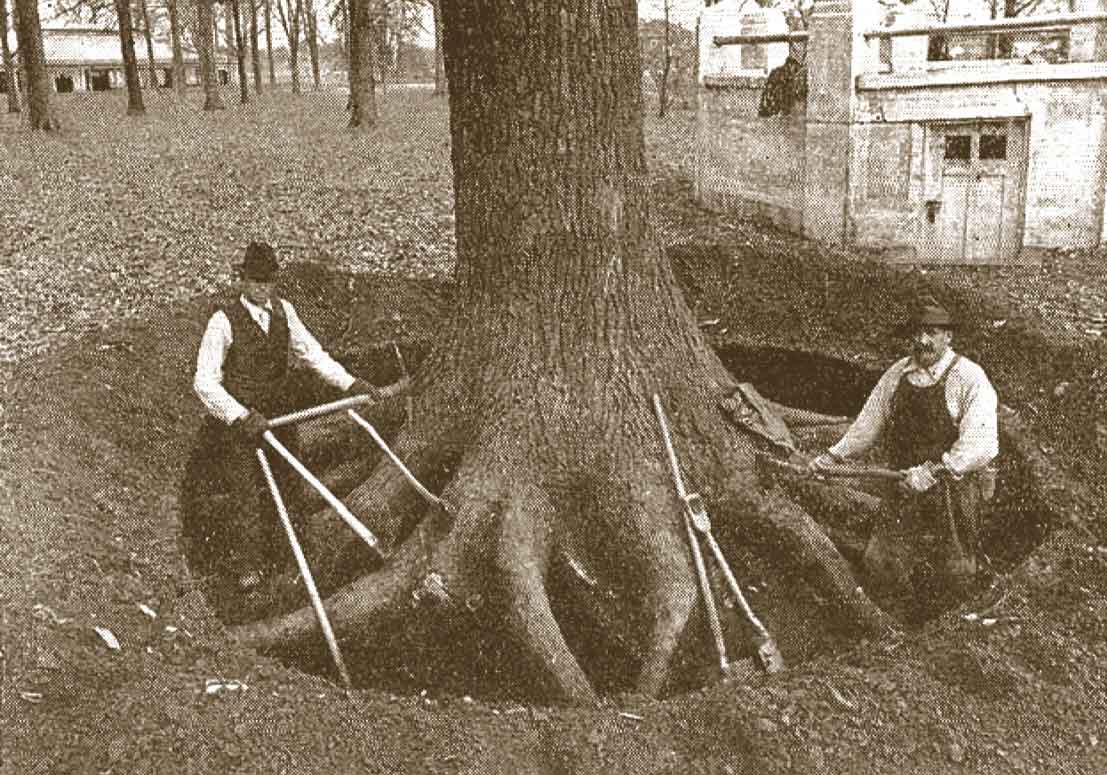

Walnut Stump Veneers Figure 5. Grubbing a Walnut Tree—Showing a good method of preparing the ground for trimming and felling.

Figure 5. Grubbing a Walnut Tree—Showing a good method of preparing the ground for trimming and felling.

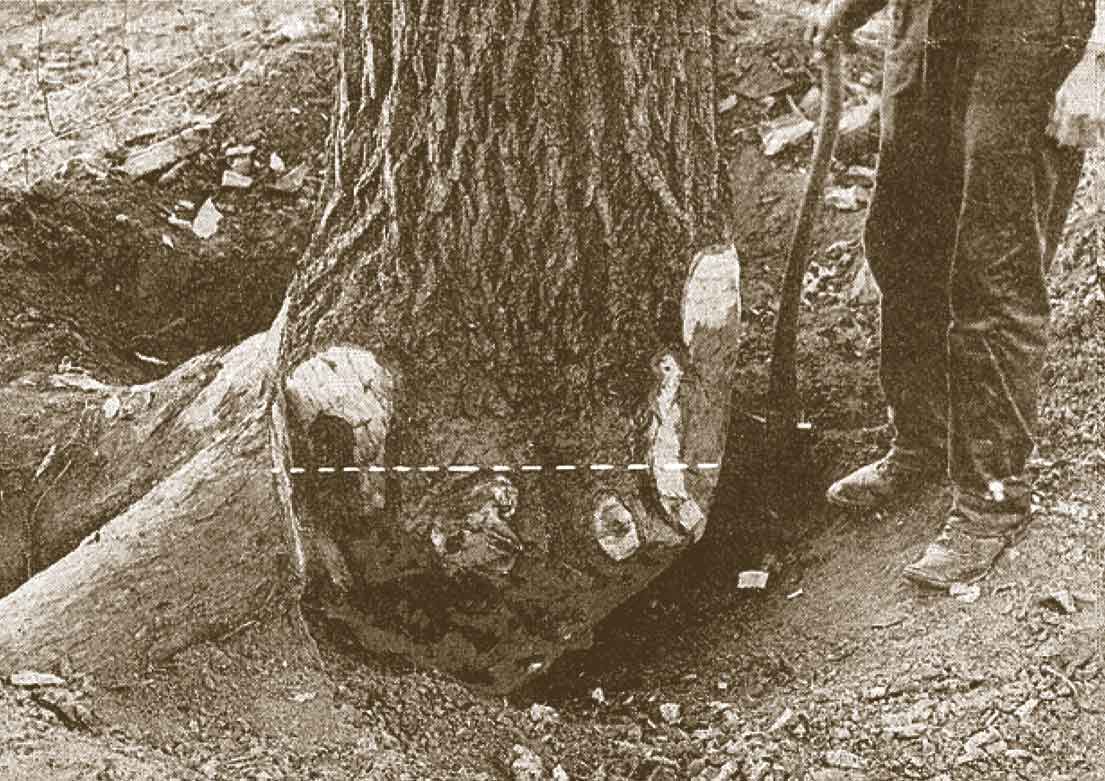

Stumps are used for veneers because many stumps contain a curly figure in the lower half. Also, because they are bell-shaped at the base they produce a grain figure. The good stump veneer usually shows both types of figure.  Figure 6. Shows how to trim back the big spur roots before felling a tree with the stump. Dotted line shows where to cut off the root wad.The stump that has no curly figure is scarcely more than a short piece of plain veneer. Figure No. 9 shows a good piece of stump veneer. Figure No. 10 shows a poor piece of stump veneer.

Figure 6. Shows how to trim back the big spur roots before felling a tree with the stump. Dotted line shows where to cut off the root wad.The stump that has no curly figure is scarcely more than a short piece of plain veneer. Figure No. 9 shows a good piece of stump veneer. Figure No. 10 shows a poor piece of stump veneer.

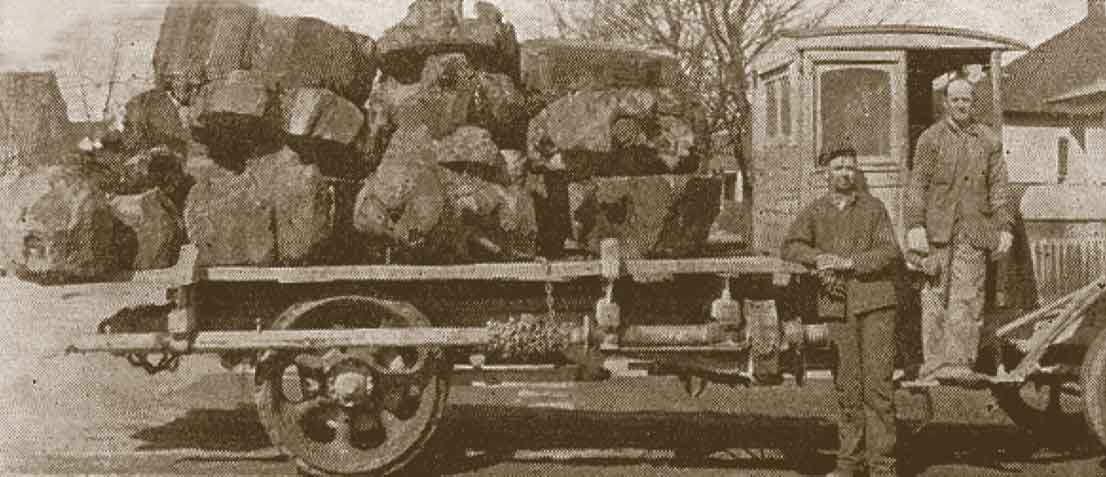

Figure 7. The Bone Yard—Worthless stumps, root wads and cull logs not worth cutting. Acres of this stuff reduce the profits of log producer and mill man.

Figure 7. The Bone Yard—Worthless stumps, root wads and cull logs not worth cutting. Acres of this stuff reduce the profits of log producer and mill man.  Figure 8. Disposal of Root Wads—You can’t split them up for wood, therefore, can’t give them away. They accumulate fast and are expensive to remove. Editor’s Note: Material is from the files of Roy Brundage, Professor, Department of Forestry and Natural Resources, Purdue University 1930 to 1971. Roy was a Wood Products Marketing Specialist and also Secretary-Treasurer of the Indiana Harwood Lumbermen’s Association. These files were passed by Roy to Dan Cassens, Professor Emeritus, Department of Forestry and Natural Resources, Purdue University, about 40 years ago. They are in the process of being transferred to Purdue Archives. Professor Brundage’s photo collection was transferred earlier.

Figure 8. Disposal of Root Wads—You can’t split them up for wood, therefore, can’t give them away. They accumulate fast and are expensive to remove. Editor’s Note: Material is from the files of Roy Brundage, Professor, Department of Forestry and Natural Resources, Purdue University 1930 to 1971. Roy was a Wood Products Marketing Specialist and also Secretary-Treasurer of the Indiana Harwood Lumbermen’s Association. These files were passed by Roy to Dan Cassens, Professor Emeritus, Department of Forestry and Natural Resources, Purdue University, about 40 years ago. They are in the process of being transferred to Purdue Archives. Professor Brundage’s photo collection was transferred earlier. Figure 9. A piece of beautifully figured stump veneer. Notice that it is figured and the freedom from defect.

Figure 9. A piece of beautifully figured stump veneer. Notice that it is figured and the freedom from defect. Figure 10. A piece of plain stump wood, even when free from defects, will not bring what it cost. This tree should have been cut off near the ground.

Figure 10. A piece of plain stump wood, even when free from defects, will not bring what it cost. This tree should have been cut off near the ground. Figure 11. A piece of matched veneer obtained by joining sections of veneer similar to those shown in Figure 9.

Figure 11. A piece of matched veneer obtained by joining sections of veneer similar to those shown in Figure 9.